A. Collection of sample/herbs

- Suitable time for collection

- The amount of a constituent is usually not constant throughout the life of a plant.

- The stage at which a plant is collected or harvested is, therefore, very important for maximizing the yield of the desired constituent.

- The differences are sometimes not only quantitative but also qualitative.

B. Rules for collection

- The following general rules are based on assuming that the material is best collected when the organ in question has reached its optimal state of development:

- Roots and rhizomes are collected at the end of the vegetation period, i.e. usually in the autumn. In most cases they must be washed free of adhering soil and sand.

- Bark is collected in the spring.

- Leavesand herbsare collected at the flowering stage.

- Flowersare usually gathered when fully developed.

- Fruitsand seedsare collected when fully ripe.

C. Methods of collection

- Medicinal plants must be largely collected by hand. This is especially true in the case of wild plants.

- With cultivation on a large scale, it may be possible to use modern agricultural harvesters, but in many cases, e.g. barks, manual collection is unavoidable. Thus, the cost of drug production is largely the cost of the labor involved.

- Preservation of plant material

- The plant material must first be preserved so that the active compounds will remain unchanged during transport and storage.

- The cells of living plants contain not only low molecular-weight compounds and enzymes, but they also have many kinds of barriers that keep these constituents apart. When the plant dies, the barriers are quickly broken down and the enzymes then get the opportunity to promote various chemical changes in the other cell constituents, e.g. by oxidation or hydrolysis. Preservation aims at limiting these processes as far as possible.

A. Drying

- The most common method for preserving plant material is drying.

- Enzymic processes take place in aqueous solution. Rapid removal of the water from the cell will, therefore, largely prevent degradation of the cell constituents.

- Drying also decreases the risk of external attack, e.g. by moulds.

- Living plant material has a high water content: leaves may contain 60-90% water, roots and rhizomes 70-85%, and wood 40-50%. The lowest percentage, often no more than 5-10%, is found in seeds.

- To stop the enzymic processes, the water content must be brought down to about 10 %.

- Drying must be done quickly, in other words at raised temperatures and with rapid and efficient removal of the water vapor.

- The most efficient drying is achieved in large driers of the tunnel type. The plant material is spread out on shallow trays, which are placed on mobile racks and passed into a tunnel where they meet a stream of warm air.

- The air temperature is kept at 20-40 °C for thin materials such as leaves, but is often raised to 60-70 °C for plant parts that are harder to dry, e.g. roots and barks.

- When the crude drug has been collected under primitive conditions, without access to a drier, it must be dried in the open. Even then, the material should be spread out in shallow layers with good ventilation to facilitate the drying. The choice of sunshine or shade is determined by the sensitivity to light of the constituents.

- In a dried drug the enzymes are not destroyed but only rendered inactive due to the low water content. As soon as water is added, they become active again. Hence, dried drugs must be protected from moisture during storage.

B. Freeze-drying

- Freeze-drying (lyophilization) is a very mild method.

- Frozen material is placed in an evacuated apparatus which has a cold surface maintained at -60 to -80 °C. Water vapor from the frozen material then passes rapidly to the cold surface.

- The method requires a relatively complicated apparatus and is much more expensive than hot-air drying. For this reason, it is not used as a routine method, but it is very important for drying heat-sensitive substances, e.g. antibiotics and proteins.

C. Stabilization

- On long storage, enzymic reactions will slowly destroy the constituents, because the last traces of water can never be removed.

- In order to avoid this degradation, the enzymes should be destroyed before drying, a process usually called stabilization.

- The most common method being brief exposure (a few minutes only) of the plant material to ethanol vapor under pressure (0.5 atm).

- Stabilization may be of value for the isolation of compounds that are very susceptible to enzymic degradation.

D. Fermentation

- Enzymic transformation of the original plant constituents is sometimes desirable.

- The fresh material is then placed in thick layers, sometimes covered and often exposed to raised temperatures (30-40 °C) and humidity, so as to accelerate the enzymic processes. (This treatment is usually called fermentation).

- The fermented product must, of course, be dried afterwards to prevent attack by microorganisms, e.g. moulds.

- Fermentation is mostly used to remove bitter or unpleasant-tasting substances or to promote the formation of aromatic compounds with a pleasant smell or taste.

- It is mainly applied to drugs used as spices or stimulants, e.g. vanilla, tea and cacao.

- Storage of crude drugs

- There are great differences in the stability of crude drugs because of slow enzymic changes in the constituents.

- Drugs containing glycosides and esters are usually less stable than those containing alkaloids.

- Drugs with essential oils deteriorate rather quickly through evaporation, oxidation and polymerization of the substances constituting the essential oil.

- Tannins on the other hand, have an almost unlimited durability.

In order to keep crude drugs as long as possible:

- It is essential to store them in a dry condition in carefully closed containers.

- It is also advisable to exclude light, because - even if it does not affect the active constituents - it almost always causes changes in the appearance of the drug, especially loss of color.

- It is also necessary to protect the drug against insect attack.

- Grinding of crude drugs

- Regardless of whether the crude drug is to be used for isolation of a pure compound or for manufacture of a simple preparation, the first operation that must be performed is grinding of the plant material to a powder of suitable particle size.

- It is important that the particles are of as uniform a size as possible.

- Excessive dust can clog percolators and result in a turbid extract which is hard to clarify.

- Large particles take a longer time for complete extraction than small ones and large differences in particle size thus slow down the extraction process.

Several types of machines are available for grinding crude drugs:

- Hammer mill; a common type for grinding crude drugs.

- Knife mill; is useful for production of low-dust powders of leaves, barks and roots for subsequent percolation or maceration.

- Tooth mill; is used for production of very fine powders.

- Grinding produces a certain amount of heat which must be observed when grinding crude drugs containing heat-sensitive compounds.

- Mills cooled with liquid nitrogen are available for such purposes.

- Cold grinding is also preferable for crude drugs containing volatile oils.

- Following grinding, the material must be sifted to ensure the proper particle size.

- Sifting can be performed according to two different principles: sievingand blast sifting.

- Sieving

In sieving the material is passed through a sieve of suitable mesh size giving two fractions. The fraction passing the sieve consists of particles with a size smaller than or corresponding to the mesh size. The remaining fraction consists of coarser particles which are returned to the mill for continued grinding.

- Blast sifting

In blast sifting the material to be classified is blown with compressed air into an apparatus which allows the particles to sediment according to their weight. Coarse, heavy particles settle fast whereas small, light particles stay for a long time in the air stream.

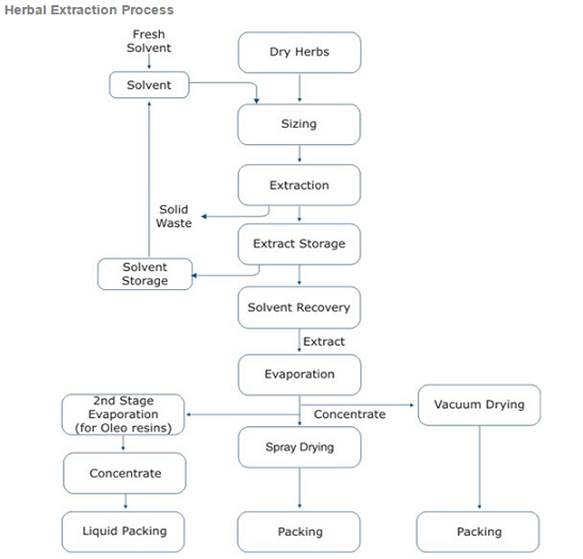

5. Extracts

- Extracts can be defined as preparations of crude drugs which contain all the constituents which are soluble in the solvent used in making the extract.

- In dry extracts all solvent has been removed.

- Soft extracts and fluid extracts are prepared with mixtures of water and ethanol as solvent.

- Tinctures are prepared by extraction of the crude drug with five to ten parts of ethanol of varying concentration, without concentration of the final product.

- For both extracts and tinctures the ratio drug/solvent should always be stated.

- Several factors influence the extraction process.

- Plant constituents are usually contained inside the cells. Therefore, The solvent used for extraction must diffuse into the cell to dissolve the desired compounds whereupon the solution must pass the cell wall in the opposite direction and mix with the surrounding liquid.

- An equilibrium is established between the sosurrounding the fragmented plant tissues.

- The speed lute inside the cells and the solvent with which this equilibrium is established depends on:

- Temperature

pH

Particle size

The movement of the solvent

Choice of solvent - The ideal solvent for a certain pharmacologically active constituent should:

- Be highly selective for the compound to be extracted.

- Have a high capacity for extraction in terms of coefficient of saturation of the compound in the medium.

- Not react with the extracted compound or with other compounds in the plant material.

- Have a low price.

- Be harmless to man and to the environment.

- Be completely volatile.

- Aliphatic alcohols with up to three carbon atoms, or mixtures of the alcohols with water, are the solvents with the greatest extractive power for almost all natural substances of low molecular weight like alkaloids, saponins and flavonoids.

- According to the pharmacopoeias, ethyl alcohol is the solvent of choice for obtaining classic extracts such as tinctures and fluid, soft and dry extracts.

- The ethanol is usually mixed with water to induce swelling of the plant particles and to increase the porosity of the cell walls which facilitates the diffusion of extracted substances from inside the cells to the surrounding solvent.

- For extraction of barks, roots, woody parts and seeds the ideal alcohol/water ratio is about 7:3 or 8:2. For leaves or aerial green parts the ratio 1:1 is usually preferred in order to avoid extraction of chlorophyll.

Extraction procedures

There are many procedures for obtaining extracts like:

- Infusion

- Maceration

- Percolation

- Digestion

- Decoction

- Continuous hot extraction

- Solvent-solvent precipitation

- Liquid-liquid extraction

- Distillation

- Specific procedures

- Infusion:

In this method, the plant material (herbal tea) is placed in a pot and wetted with cold water. Immediately afterwards, boiling water is poured over it, then left to stand, covered with a lid, for about fifteen minutes after which the tea is poured off.

- Maceration:

This method is used frequently for water soluble active constituents. It consists of macerating the plant material in cold water (15-20°) for several hours.

- Percolation:

In this method, the ground plant material is subjected to a slow flow of fresh solvent.

- Digestion:

This method is suitable for hard barks or woods which are difficult for water to penetrate. Digestion is also considered as maceration but, at a relatively elevated temperature. As a general rule the temperature of the extracting medium should be in the range from 35-40° but not exceeding 50°.

- Decoction:

If the plant material is boiled for ten minutes or if boiling water is poured over it and allowed to stand for thirty minutes, the result is called decoction.

- Continuous hot extraction method:

This procedure is considered as the most common method used for the extraction of organic constituents from dried plant tissue. It can be used both on laboratory and industrial scales. In the lab, the powdered material is continuously extracted in a Soxhlet apparatus with a range of solvents of increasing polarity.

- Solvent-solvent precipitation:

(I) The extract dissolved in a suitable solvent, is mixed with a less polar but miscible solvent causing the selective precipitation of the less soluble plant constituent, e.g. the precipitation of triterpenoid saponins from the methanol extract of Phytolacca dodecandra by the addition of acetone and the precipitation of gum from aqueous extracts of Olibanum by addition of alcohol.

(II) By the addition of the extract to a solvent in which the constituents is insoluble or very sparingly soluble e.g. precipitation of resins from the alcoholic extracts by the addition of distilled or acidulated water.

- Liquid-liquid extraction:

Liquid-liquid extraction, also known as solvent extraction and partitioning, is a method to separate compounds based on their relative solubilities in two different immiscible liquids, usually water and an organic solvent. It is an extraction of a substance from one liquid phase into another liquid phase.

Liquid-liquid extraction is a basic technique in phytochemical laboratories, where it is performed using a separatory funnel.